Dip coating Q&A

- What kind of device is a dip coater (dip coating method)?

- What film thickness can be obtained by the dip coating method?

- Please tell me how to control the film thickness of the dip coat. Also, how accurate is the film thickness?

- I would like to arrange particles. Is it possible with your company's dip coater?

- What are the features of SDI's dip coating equipment (dip coater)?

- Is it possible to change the speed during dip coating?

- What kind of substrates (workpieces) can be used for dip coating?

- What is the repeatability of the dip coater equipment?

- What is the method of operation?

- Is it possible to manufacture a tank for dip coating?

- What should I pay attention to in the usage environment when introducing a dip coater?

- What is the difference from other coating methods?

- How much does the dip coating equipment cost?

- What is the delivery time for the dip coater?

- What kind of delivery record do you have?

- Is it possible to manufacture jigs for dip coaters?

- What are the maintenance requirements for the dip coater?

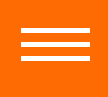

1. What kind of device is a dip coater (dip coating method)?

This equipment forms a thin film on both sides at the same time by immersing the workpiece (substrate) to be dip-coated in the dip-coating solution and pulling it upward. It is used in manufacturing and research in many fields, such as spectacle lenses, surface hardener coating for polycarbonate and acrylic materials, printed circuit boards, resist coating on glass, and particle arrangement on glass.

At SDI, we offer a wide range of lineups, from tabletop dip coaters for experiments to dip coaters for manufacturing.

At SDI, we offer a wide range of lineups, from tabletop dip coaters for experiments to dip coaters for manufacturing.

2. What film thickness can be obtained by the dip coating method?

Film thickness can range from several nanometers to several tens of micrometers, but it is not suitable for thick films.

3. Please tell me how to control the film thickness of the dip coat. Also, how accurate is the film thickness?

A feature of the dip coating method is that the slower the dip (pull-up) speed, the thinner the film. Conversely, the faster the dipping speed, the thicker the film. SDI dip coaters are capable of ultra-low speeds down to 1 nm/sec, making it possible to arrange particles on the work surface.

The film thickness accuracy is usually around ±10%, but the thinner the film, the higher the accuracy tends to be.

However, please note that it is greatly influenced by the characteristics of the coating liquid used for dip coating.

The film thickness accuracy is usually around ±10%, but the thinner the film, the higher the accuracy tends to be.

However, please note that it is greatly influenced by the characteristics of the coating liquid used for dip coating.

4. I would like to arrange particles. Is it possible with your company's dip coater?

Is possible. There are examples of Nano Speed Dip Coater and Micro Speed Dip Coater. Please refer to dip coating example on HP.

5. What are the features of SDI's dip coating equipment (dip coater)?

We have a diverse lineup from ultra-low speed specifications to mass production equipment. Basically, it is a customized specification, and we are trying to provide original equipment. In the product Nine-up, the speed range of the dip coater covers a wide range of processing speeds from 1 nm/sec to 200 mm/sec, and uniform thin film formation is possible due to speed unevenness and low vibration. In addition, the touch panel system enables easy operation. Of course, PC support is also possible.

Please refer to the video on HP.

video

Please refer to the video on HP.

video

6. Is it possible to change the speed during dip coating?

Yes. It is possible. Dip speed can be changed at 8 to 16 points (there are differences for each model).

7. What kind of substrates (workpieces) can be used for dip coating?

We have a wide variety of materials such as eyeglass lenses, polycarbonate, acrylic, SUS, printed circuit boards, glass, catheters, medical tubes, medical needles, and other metals. You can use it regardless of the field.

8. What is the repeatability of the dip coater equipment?

There is data for our micro speed dip coater (model: MD-0408-S5).

Please contact us.

Please contact us.

10. Is it possible to manufacture a tank for dip coating?

Of course it is possible. Depending on the characteristics of the dip coat liquid, we will prepare it if you specify the material and size.

11. What should I pay attention to in the usage environment when introducing a dip coater?

Vibration and wind are factors that affect film thickness during dip coating. Vibration is the natural vibration of the building, and wind is mainly caused by air conditioning. Therefore, it may be necessary to use an anti-vibration table for vibration and a windbreak box for wind.

SDI provides a dedicated anti-vibration table for the dip coater and a dedicated windshield box.

SDI provides a dedicated anti-vibration table for the dip coater and a dedicated windshield box.

12. What is the difference from other coating methods?

The greatest feature of the dip coating method is that thin films can be easily formed on both sides at the same time. again,

High efficiency of coating solution: No waste of solution and very little coating unevenness. A dip coater is very economical because the thinner the film, the less amount of solution it uses.

Non-flat surfaces can be coated: Impregnation with a coating liquid enables coating on non-flat surfaces (both sides, porous bodies, protrusions, etc.).

Non-flat surfaces can be coated: Impregnation with a coating liquid enables coating on non-flat surfaces (both sides, porous bodies, protrusions, etc.).

13. How much does the dip coating equipment cost?

Please use the HP catalog download. The price for the standard dip coater is listed, but please contact us for special order dip coaters and customization.

14. What is the delivery time for the dip coater?

The standard delivery time for a normal dip coater is 45 days after receiving an order.

In the case of a special order dip coater, please contact us separately. Please feel free to contact us.

In the case of a special order dip coater, please contact us separately. Please feel free to contact us.

15. What kind of delivery record do you have?

See below for a list of SDI dip coater suppliers. We deliver to a wide variety of fields such as public institutions, schools, manufacturers, and overseas.

List of delivery records

List of delivery records

16. Is it possible to manufacture jigs for dip coaters?

Is possible. I think there are as many jigs as there are customers.

We will provide the best matching jigs by making use of our manufacturing experience of many jigs.

We will provide the best matching jigs by making use of our manufacturing experience of many jigs.

17. What are the maintenance requirements for the dip coater?

The inspection items for the standard equipment are as follows. (Items not compatible with some models are included)

*Inspection items

This section describes items for daily inspection and periodic inspection under normal operating conditions.

*Daily inspection

*Inspection items

This section describes items for daily inspection and periodic inspection under normal operating conditions.

*Daily inspection

- Is the operating environment within specifications?

- Is there any abnormal vibration or noise from the main unit or control box?

- Is there any odor from the control box?

- Is there any foreign matter inside the main unit or control box?

- Are the connector connections loose or disconnected?

- Is the wiring cable between the main unit and the control box damaged?

- Are there any chemicals or stains on the clips?

- Is the power supply voltage normal?

- Is the body damaged?

- Has the operating data been changed?

- Is the controller battery (battery) exhausted?

- Is there any abnormal vibration from the drive part of the main unit?

- Is there any abnormal vibration or noise from the fan inside the control box?

- Are the wiring damaged?

- Are the clip springs broken?

- Do not loosen the screws of the drive connection parts (such as the DIP arm of the main unit).

Japanease

Japanease English

English