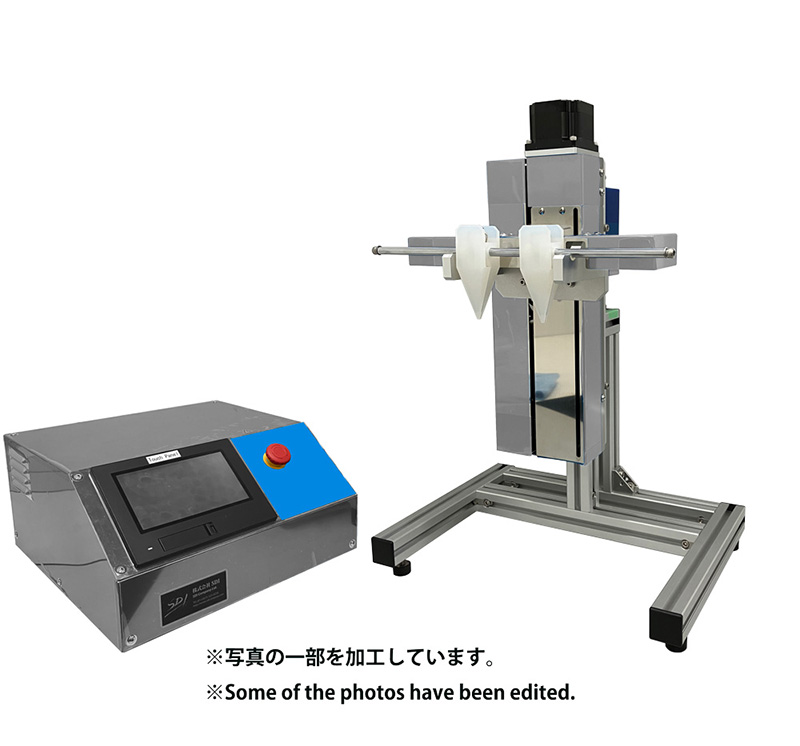

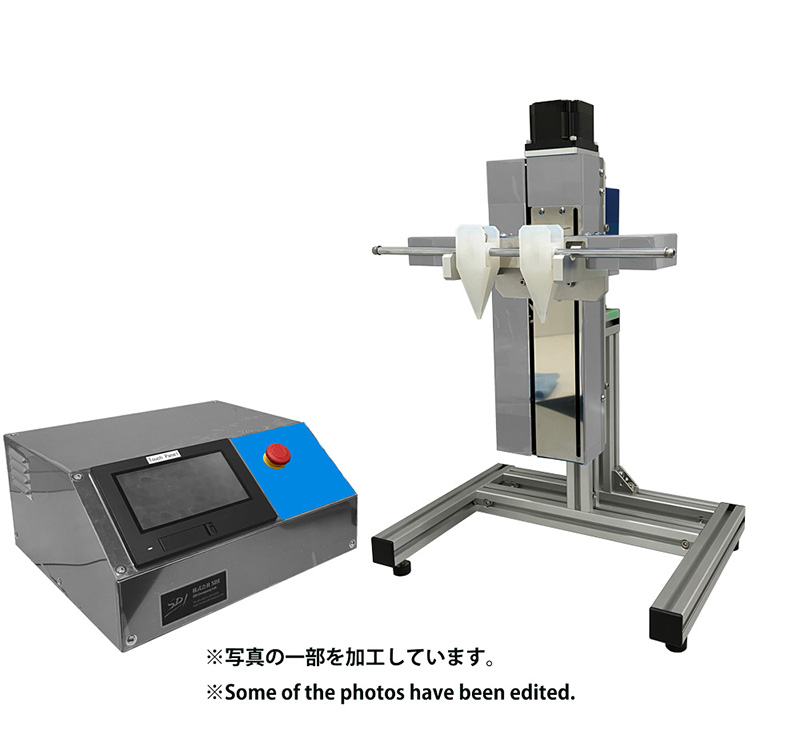

Micro dip ® coater MD-0408-N1-CE

Desktop device for experiments / research / development Specifications /

[This product is CE marking compliant in accordance with the applicable EU directives.]

High-precision speed control from 1 nm/sec to 60 mm/sec. A research-grade dip coater that shows its true value in the ultra-low speed range.

-

The Micro Dip® Coater is an ultra-low speed dip coater that allows for a wide range of speed control, from 1 nm/sec to 60 mm/sec. It is optimized for research into separation film generation, particle arrangement, and thin film formation, which require nano-level film thickness control. Up to 16 speed settings and eight operation patterns can be registered, supporting highly reproducible coating experiments. The touch panel allows intuitive changes to speeds and operation patterns, as well as repeat settings, and the display can be switched between Japanese and English. Developed under the supervision of Tsukuba AIST, this model for researchers combines precision control and high-level operability.

| Main Specifications | |

|---|---|

| Stroke | 150mm |

| Minimum Speed (Min.) | 1nm/sec |

| Maximum Speed (Max) | 60mm/sec |

| Operating Method | Touch Panel |

| Screen Indication Language | Japanese / English |

| Number of designation points for Transaction Speeds | 16 Points |

| Number of designation points for Stop Positions | 16 Points |

| Number of designation points for Stopping Time | 16 Points |

| Consecutive Driving Mode | Equipped |

| Manual Driving Mode | Equipped |

| Number of Memorized Programs | 8 Programs |

| Monitoring Function: Present Speed | Equipped |

| Monitoring Function: Present Position | Equipped |

| Residual Time of Monitoring | Equipped |

| Repetition Driving | Equipped |

| Standard Clip | Material: Polypropylene (PP) |

| Utility | AC100V-240V, 300VA |

| Maximum Weight Capacity | 1kg |

| Maximum Processing Size (mm) | H:150mm |

| Equipment Dimension (mm): not including projections | W:350 D:256 H507:(9kg) |

| Control Box Dimension (mm) : not including projections | W:380 D:400 H:200(10kg) |

Japanease

Japanease English

English