Company History

Steps of SDI Company Ltd. & Dip Coaters (Dip Coating Equipments)

-

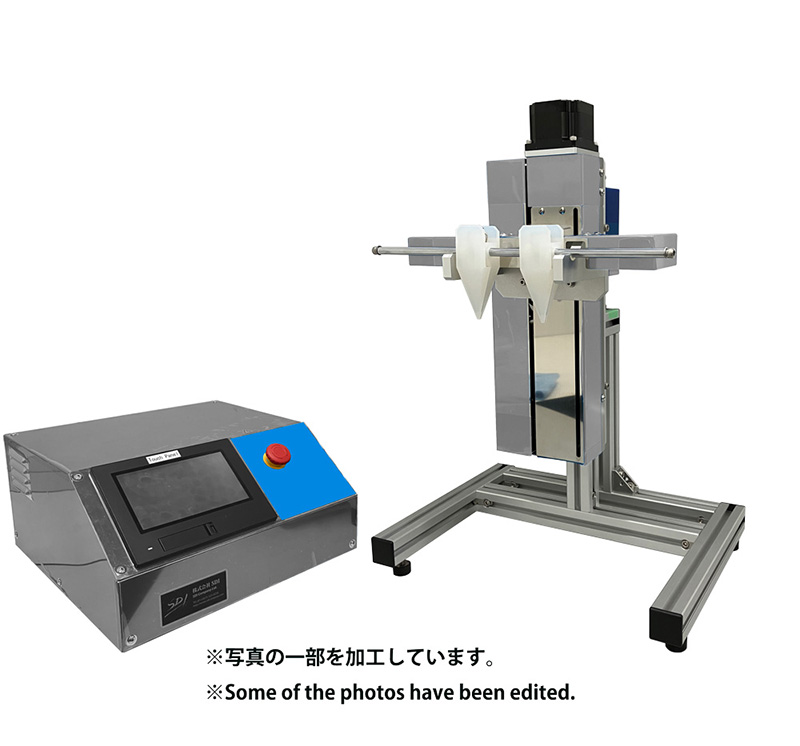

We, since 1997, have been engaging the business about the Dip Coaters (Dip Coating Equipments) starting with [Full Automatic Dip Coater (Dip Coating Equipment)] which is a manufacturing equipment of printed circuit boards.

Thereafter, with an opportunity of the request to produce desktop Dip Coater (Dip Coating Unit) for the development & the experiment uses, which came from one of manufacturer about Dip Coat Liquid using for Dip Coaters (Dip Coating Equipments), then we started to deal the production and its sale with DT Series that are Dip Coaters (Dip Coating Equipments) of development & experiment uses.

In year 2004, after we removed to Kyoto-Research-Park, we were requested to develop & produce [Super Low Speed Dip Coater] from Kyoto University then we have come up to develop and produce [Nano Dip Coater] (ND-0407) which was the lowest speed in this industry in those days.

Our [Nano Dip Coater] was adopted as [2004 business plan possibility support project] (* cf. photograph A) promoted by “(Foundation) Kyoto Industrial Support Organization 21”, then we have planed later year development of the business about Dip Coaters (Dip Coating Equipments) based on the [Investigative Report of Feasibility Study about Super Lowe Speed Dip Coaters] shown in (* cf. photograph B).

We have been straining on the Super Low Speed Dip Coaters (Dip Coating Equipments) and Touch Panel Controlling Method.

It led to the advance forwarding totally new fields from the conventional Dip Coat use fields by realizing this speed of Super Low Speed Dip Coaters (Dip Coating Equipments).

Before the realizing to enable Nano-level Controlling, the market of sale for Dip Coaters (Dip Coating Equipments) was Printed Circuit Board makers mainly, but now, current business form of Dip Coaters (Dip Coating Equipments) was completed with many consultations & inquiries from a lot of University Laboratories, Public Organizations including “The National Institute of Advanced Industrial Science and Technology (AIST)”and R&D sections of Private Enterprises who have been doing research concerning with Opal Films, Photonic Crystals, Photocatalysts, Sun-light Panels, Electronic Devices, Optical Lens, Surface Treatment and Materials Science, etc.

We are highly appreciating to opinions and advices without the reserve from all of them, although there could be the thing we were given kind advices and admonitions from many teachers.

As the reason we selected Touch Panel Method, we originally had launched the Dip Coater Business as a production device, therefore we considered that it should be better method that anyone is easy to operate on the site, however even if cost increases a little.

We suppose that this is slightly different point from conventional makers providing Research & Development Devices, who are considering even a little cost down.

Our thrust is the realization of the devices/equipments which, thoroughly in a researcher's-eye view line, anyone can understand & operate easily and the researchers can feel satisfaction as it was really good to purchase SDI Dip Coaters (Dip Coating Equipments) and the result of their research / study were able to be achieved. Therefore we think that a little additional cost is no help for it.

We devoutly and earnestly wish that SDI Dip Coaters (Dip Coating Equipments) shall be kindly utilized, be loved by numerous persons in charge of R&D and shall be able to achieve much result from now on too.

In addition, we, all the staff, gratefully will devote to develop of better & finer devices increasingly.

-

![[2004 business plan possibility support project]](images/img-siryo.jpg)

History

| 2019 October | Start mass production of contract coating business |

| 2019 August | Starts atmospheric pressure plasma business |

| 2015 December | Introduced 3D printer. Supports speedy jig production Adopted as a 2014 amendment / manufacturing / commercial / service innovation subsidy [Development of a dip coater that enables uniform and thin film formation even on complex three-dimensional surfaces] 2013 amendment, adopted for small and medium-sized enterprises, small business manufacturing, commerce, and service innovation projects [Development of dip coater that enables narrower pitch and thinner base material] |

| 2009 September | Certified as the programs of specific research & development under the “Act on Enhancement of Small and Medium Sized Enterprises' Core Manufacturing Technology” |

| 2009 April | Starting the business of contracted Coating Treatment |

| 2008 February | Head-office moving in Advanced Scientific Technology & Management Research Institute of Kyoto (ASTEM RI / KYOTO) |

| 2007 September | Launching the Electronic Parts Business |

| 2007 July | Authorized in the ranking by Kyoto-City Venture Company MEKIKI Committee |

| 2007 May | Launching the Heat-Treatment Business |

| 2007 January | Acquisition of “KES Environmental Management System Standard Step 2” certification |

| 2006 March | Head-office moving to Shijyo-Karasuma |

| 2004 September | Nano Dipcoater is adopted as [2004 business plan possibility support project] promoted by (Foundation) Kyoto Industrial Support Organization 21. (applied by Shimadzu General Services, Inc.) |

| 2004 April | Setting up engineering department |

| 2004 April | Head-office moving in Advanced Scientific Technology & Management Research Institute of Kyoto (ASTEM RI / KYOTO) |

| 2004 February | Reorganization to SDK Company Ltd. Capital for JP Yen 10,000,000. |

| 2003 March | An achievement of the development for Experimental Desk-top Dipcoater (DT-0303) of industry is first and starting the production and sales |

| 1998 November | The first shipment of Full Automatic Dipcoater toward Overseas Customer |

| 1998 May | Capital Increase up to JP Yen 5,000,000.- |

| 1997 July | Establishment of SDI Company LLC as a sales company for Dipcoaters Contributed Capital for JP Yen 3,000,000. |

Japanease

Japanease English

English