- The Features of SDI Dip Coaters

- WHAT IS THE DIP COATER?

- About Fine Particles Array

- Summary of the Dip Coating System

What is the Dip Coating (Dip Coat)?

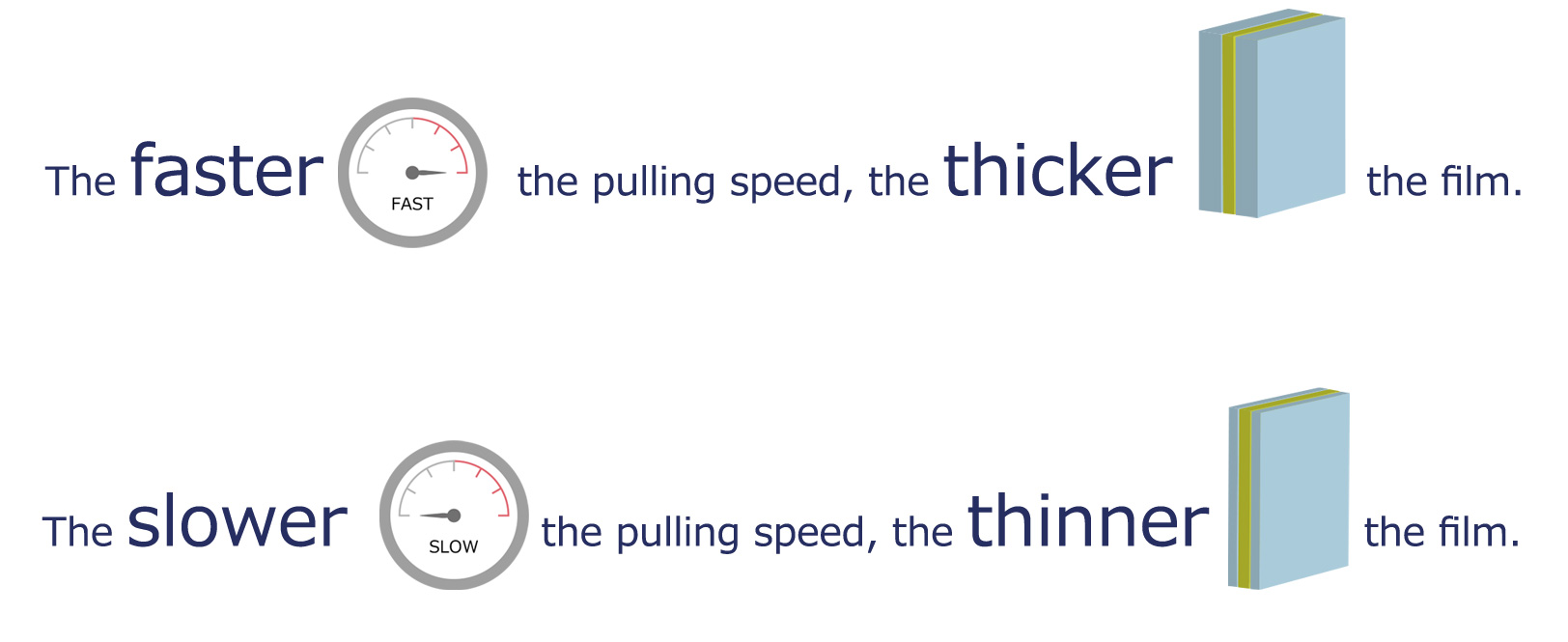

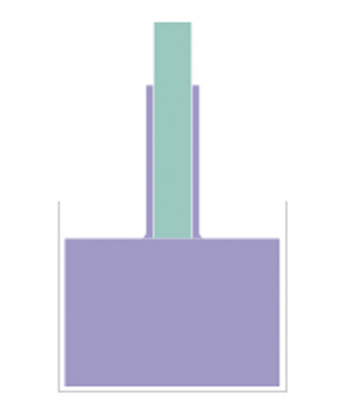

Thin Film Formation

Dip Coating (Dip Coat) is the most suitable for the formation of thin film. The slower speed of Dip Coat (Dip Coating) in the Dip Coater (Dip Coating Equipment) will get [the thinner] film thickness, the faster speed of Dip Coat can make [the thicker] film thickness.

Double-side Coating

As base materials are dipped into Dip Coating Liquid, double-side shall be treated by Dip Coating at one time.

Immersed in dip coat solution

Immersed in dip coat solutionSimultaneous coating on both sides

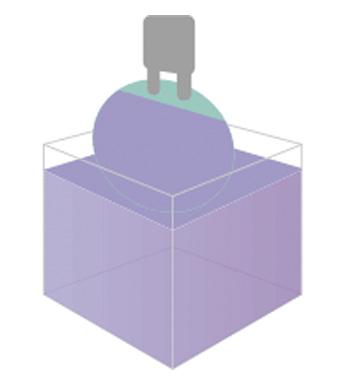

The shape of the Base Material Board does not matter == The Followability to complicated shapes

Because Dip Coating has the process which will dip the object into dip coat liquid, whole surfaces of the object materials for Dip Coat will be made with Dip Coating, so generally there is a tendency to follow the surface irregularities neatly. (There are cases when it will be changed depending on the peculiarity of coating liquid.)

dip coat material

dip coat materialCoating the entire surface

Low Cost

The function of Dip Coaters (Dip Coating Equipments) is simple and productions by low cost are available.

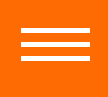

Dip coating equipment

Dip coating equipmentlow cost

Easy and Simple Maintenance

As the system of Dip Coaters (Dip Coating Equipments) is not complicated function, that maintenance is easy and simple.

Dip coating equipment

Dip coating equipmentEasy maintenance

A little loss of Dip Coat Liquid

Because there is no scatter of Dip Coat Liquid during Dip Coating work, no loss of Dip Coat Liquid.

No dip coating liquid loss

No dip coating liquid loss Japanease

Japanease English

English