- The Features of SDI Dip Coaters

- WHAT IS THE DIP COATER?

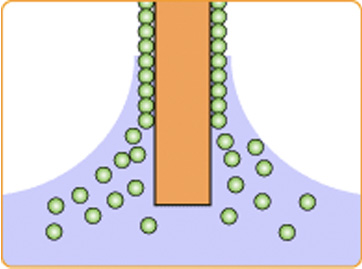

- About Fine Particles Array

- Summary of the Dip Coating System

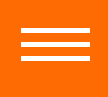

The Features of SDI Dip Coaters (Dip Coating Equipments)

Depending on Base Materials (Coating Application Objects) of its Dip Coating and the kind of Dip Coating Liquid (Dip Coat Liquid), various kinds of equipments in different specifications which can correspond to different Dip Coat Speeds (Dipping Coating Speeds), Dip Strokes and Dip Speed Adjusting Formation, etc. are required for the Dip Coaters (Dip Coating Equipments) using to the Dip Coat (Dip Coating).

Based on our many year experiences and production results, we have been attempting to match to our customers’ needs and will provide you of your own “My Dip Coater”, we are keeping it in our mind.

Depends on models, the Features of our Dip Coaters (Dip Coating Equipments) are followings;

This industry’s highest standard of the Super Slow action Speed (1 nano meter/sec.) specification was realized.

This industry’s highest standard of the Super Slow action Speed (1 nano meter/sec.) specification was realized. ->ND Series

Kinds of Models are abundance.

MD Series of Low Speed (1 um/sec.), DT Series of multipurpose speed (0.1 mm/sec.), portable type, other various kinds and so on.

Less vibration and Stable Raising-up Speed

Formation of the uniform thin film can be done.

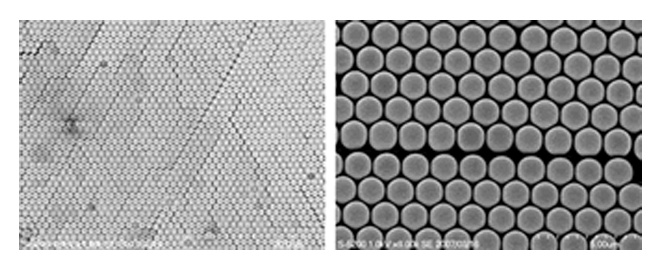

An example of Fine Particles Array by Dip Coating

An example of Fine Particles Array by Dip Coating

Changing speed and Setting the period/time of stop at any optional points are available.

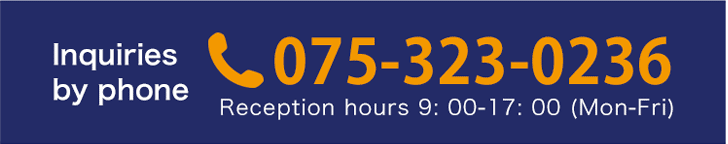

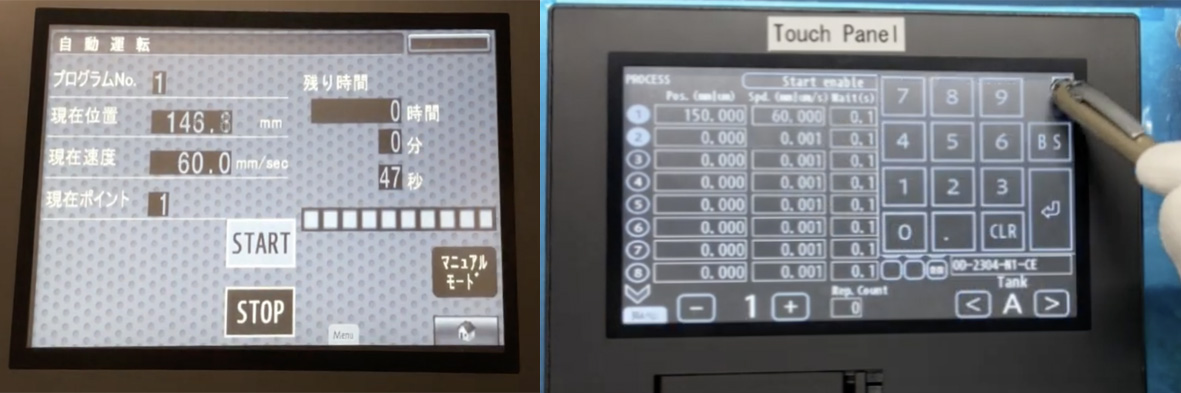

With the Function of Monitoring for current position and current speed, etc.

SDI dip coating equipment operation screen

SDI dip coating equipment operation screen

Repeating Function of the Program

Plural innings all over and over coating in a part both can be done.

The operations and the maintenances are simplified.

Easy routine maintenance

Coping with various customizations

We cope with customers’ desires and demands as per newly design & make of required Jigs, Tanks for Dip Coat (Dip Coating) Liquid, the Circulation System for Dip Coating Liquid, and so on.

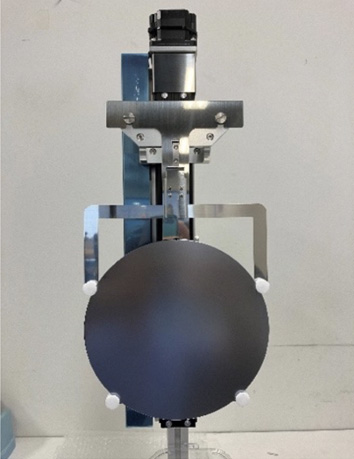

JigA

Gripping jig for 8inch wafers

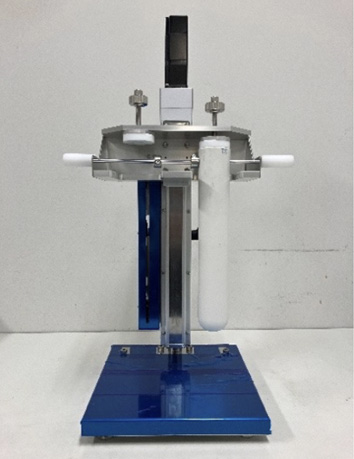

JigB

Gripping jig for φ70mm lens

JigC

Gripping jig for cylindrical ceramics

Bellow showing by diagrams about the pattern of Dip Coating speed changing;

★Linear driving mode (Applicable Model: LD-1304-S2)

This is the Dip Coating mode to produce fluent variation of film thickness with changing Dip Coating speed linearly from the appointed position A to the position B.Caution: Shape of the coating film is reference (image) only insistently. There are cases when it will be changed significantly depending on the peculiarity of coating liquid.

Caution: Shape of the coating film is reference (image) only insistently. There are cases when it will be changed significantly depending on the peculiarity of coating liquid.

-

★Consecutive driving modes (Applicable Model: All model excepting for DT-0001-N1)

This is the Dip Coating mode showing that the stopping time at the Dip Coating speed changing is Zero (0) sec. i.e., immediately changing.

Caution: Shape of the coating film is reference (image) only insistently. There are cases when it will be changed significantly depending on the peculiarity of coating liquid.

★Wait Driving Mode (Applicable Model: All model)

This is the Dip Coating Mode to alter Speed Changing Time from the shortest [0.1 sec.] to the longest [999.9 sec.] at the optionally set position to change Dip Coating Speed. This is the Dip Coating Mode in cases of necessity to drop Dip Coating Liquid and impregnation into Dip Coating base materialsCaution: Shape of the coating film is reference (image) only insistently. There are cases when it will be changed significantly depending on the peculiarity of coating liquid.

Japanease

Japanease English

English