What is a dip coater?

Representative types of coating equipment

Spray Coating

This method involves spraying the coating liquid onto the base material.[Excellent]Does not come into contact with the base material

This method involves spraying the coating liquid onto the base material.[Excellent]Does not come into contact with the base material

[Good]One-sided coating possible

[Bad]Loss of coating liquid

[Bad]Cannot be applied in thin filmsRoll Coating

applying the coating liquid to the base material with a roller .[Good]Reduces loss of coating fluid

applying the coating liquid to the base material with a roller .[Good]Reduces loss of coating fluid

[Good]One-sided coating possible

[OK]It is difficult to apply thin films

[Bad]Contact with the substrateSpin Coating

This method involves rotating the substrate and spreading the coating liquid using centrifugal force.[Excellent]Does not come into contact with the base material

This method involves rotating the substrate and spreading the coating liquid using centrifugal force.[Excellent]Does not come into contact with the base material

[Excellent]One-sided coating possible

[Good]Thin film coating is possible

[Bad]Loss of coating liquid

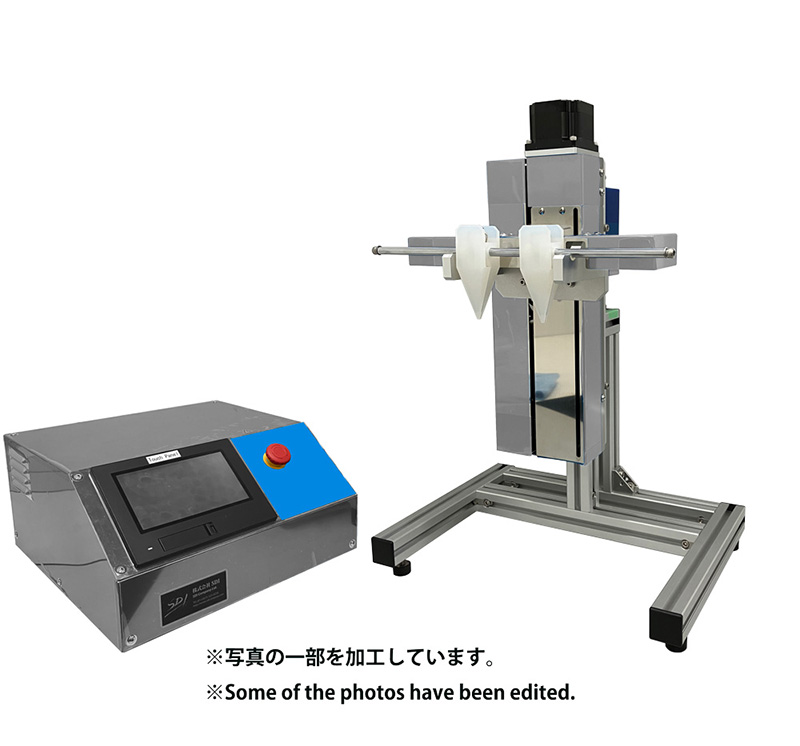

[Bad]Cannot be applied in thin filmsDip Coating

This method involves immersing the substrate in the coating liquid and then pulling it out.[Excellent]Reduces loss of coating fluid

This method involves immersing the substrate in the coating liquid and then pulling it out.[Excellent]Reduces loss of coating fluid

[Excellent]Thin film coating is possible

[Excellent]Does not come into contact with the base material

[Good]One-sided coating possible

Features of each coating device

Features of Dip Coater

Uniform thin film

By slowly pulling it up, the surface tension works and a uniform thin film is formed. The film thickness can also be controlled by the pulling speed. Dip coating with a uniform thin film

Simultaneous coating on both sides

Both sides can be coated at the same time, shortening the work process. Also, the film thickness can be controlled by the lifting speed.

Any shape

It is possible to coat substrates (objects) of any shape. Dip coating for any shape

No loss of coating fluid

There is no loss of coating liquid due to splashing or adhesion to parts. Dip coating with no loss of coating fluid

Simple Maintenance

Since it is not a complicated mechanism, maintenance is easy. Simple maintenance dip coating

Usage Example

Eyeglass lenses

Mobile phones, etc.

Display parts of mobile phones, etc. (transparent glass)

Tablet device

Automotive interior panels

Printed Circuit Board

Disaster prevention

helmet goggles

SDI device usage report

Titanium oxide photocatalyst coating using Micro Dip Coater MD-0408

The University of TokyoFabrication of polymer thin films using a micro dip coater

Osaka UniversityMicropattern formation in silica and titania films prepared by low speed dip coating

Kansai UniversityCreation of opal film using nano-dipping device

Kyoto UniversityChemical solution coating on silicon substrate using Nano Dip Coater ND-0407-S3 and the effect of substrate lifting conditions

Sophia UniversityEintesla Joint Research Report

Nihon University

Academic papers on dip coaters and dip coating

Spontaneous pattern formation on silica and titania dip-coating films prepared at extremely low substrate withdrawal speeds

H. Uchiyama, M. Hayashi, H. Kozuka, RSC Adv., 2012;2:467–473.

Preliminary Study of Quantitative Analysis of Ammonium Ions in a Raindrop Following Liesegang Ring Formation

N. Tomikawa, B. Nanzai, M. Igawa, Anal Sci. 2011;27(8):861-4.

Optical gas sensing with dip-coated carbon nanotubes through the modulation of photoluminescence and optical absorption

K. Iakoubovskii, N. Minami and A. Karthigeyana, J. Mater. Chem., 2012;22:4716-4719

Bright structural color films independent of background prepared by the dip-coating of biomimetic melanin-like particles having polydopamine shell layers

M. Kohri, S. Yamazaki, A. Kawamura, T. Taniguchi, K. Kishikawa, Coll. Surf. A., 2017;532:564-569.

Self-healing coatings of inorganic particles using a pH-sensitive organic agent

A. Yabuki, M. Sakai, Corros. Sci., 2011;53(2):829-833.

PHOTOVOLTAIC PERFORMANCE OF DYE-SENSITIZED SOLAR CELL INCORPORATED WIRE ELECTRODE

H.S. Jung, J. H. Kim, T. J. Kang, 18th International Conference on Composite Materials. Aug 21-26, 2011; ICC Jeju, Korea.

What kind of company is SDI Corporation ?

Design and manufacture of industrial dryers

Design and manufacture of printed circuit boards

PLC Control Design

General labor dispatch business

Japanease

Japanease English

English