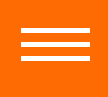

Dip coat/dip coating process and features

Dip coating is a process in which an object is immersed in a liquid and then pulled out to form a uniform film on the surface.

This technology is used in a variety of fields, including paints, coatings, electronic materials, and biomaterials. Below are the basic process of dip coating and its advantages.

Basic process

1. [Pretreatment]

Drying the object and improving adhesion. Vacuum plasma and atmospheric plasma can also be used for pretreatment.

2. [Cleaning]

Cleaning the surface of the object. There are two main methods: dry process and wet process.

3. [Dip Coat]

Substrate is immersed in coating liquid. This liquid may contain paint, polymer solution, nanoparticle dispersion, etc.

4. [Drying]

The substrate is dried, and the liquid components are evaporated to solidify the coating. Drying is done by natural drying, heating, UV curing, etc.

Relationship between pulling speed and film thickness

Generally, the faster the pulling speed is, the thicker the film will be, and the slower the speed is, the thinner the film will be. The

film thickness is controlled by adjusting the pulling speed and the temperature and viscosity of the coating agent.

Dip coating application example

- Faucet fittings: Water-repellent, hydrophilic formation.

- Shields such as helmets: Formation of a hard coat film.

- Optical devices: Formation of anti-reflective coatings and protective films.

- Medical: Manufacturing of biocompatible coatings and drug delivery systems.

- Electronic materials: manufacturing of sensors and thin film transistors.

- Automotive industry: application of anti-rust coatings and decorative films.

Due to its simplicity and versatility, dip coating has become an important technique in many industrial sectors.

Advantages and precautions of the dip coating method

advantage

-

The dip coating method is suitable for forming a uniform film over the entire surface.

-

The process is relatively simple and does not require any special equipment.

-

It can be scaled up from research and experimental levels to mass production and manufacturing levels.

-

Low capital investment and operating costs compared to other coating methods.

-

It can be applied to a variety of materials (organic and inorganic) and substrates.

-

The film thickness is controlled by adjusting the pulling speed and the viscosity of the solution.

Important points to note

- Limited film uniformity: Film uniformity may not be guaranteed, especially on substrates with complex shapes.

- Material limitations: High viscosity liquids and liquids with low volatility can be difficult to form a uniform film.

- Controlling the drying process: Failure to properly control the drying rate and temperature can result in defects in the membrane.

- Fluid usage: Coating large substrates can require large amounts of fluid, resulting in waste.

- Difficulties with multiple layers: Forming multi-layer structures can be difficult.

- Fluid stability: The properties of the coating fluid may change over time, causing variations in film quality.

While dip coating has many advantages, there are some points to be aware of for certain applications and conditions.

Understanding these points and implementing appropriate controls will help you achieve an optimal coating process.

Dip coating and other typical coating methods

Among various coating methods, the dip coating method is widely used due to its simplicity and versatility. Below, we compare the advantages and points to note of dip coating method with other representative coating methods (spin coating, slit coating, spray coating, die coating, roll coating) , and conclude by explaining the advantages of dip coating method.

Dip coating

Advantages

- Film thickness : Unlimited thin film formation possible

- Simple process: The process is simple and does not require any special equipment.

- Versatile: can be applied to a wide range of materials and substrates.

- Cost-effective: Low capital and operational costs.

- Applicability to large areas and complex shapes: Uniform films can be formed even on large-area substrates or substrates with complex shapes.

- Less material wastage: There is comparatively less wastage of material.

Important points to note

- Control of the drying process: Proper drying conditions must be maintained.

- Material limitations: May not be suitable for certain high viscosity or slow drying materials.

Spin Coating

-

Advantages

- High-precision film thickness control: A very uniform thin film can be obtained.

- Rapid process: Film can be formed in a short time.

- High reproducibility: consistent film thickness can be achieved.

-

Important points to note

- Material waste: A lot of coating fluid is splashed and wasted.

- Geometry constraints: Only applicable to flat substrates.

- Large area limitation: Not suitable for large substrates.

Slit Coating Method

-

Advantages

- High efficiency: Able to continuously form uniform films on large-area substrates.

- Material Saving: Less material wastage.

- Thickness uniformity: High film thickness uniformity.

-

Important points to note

- High cost: Large initial investment.

- Process complexity: The coating fluid is difficult to control.

- Material limitations: May not be suitable for certain materials.

Spray Coating Method

-

Advantages

- Application to complex shapes: Can be applied evenly to complex shapes.

- Wide range of material applications: A wide variety of materials can be used.

-

Important points to note

- High material waste: High material scattering and waste occurs.

- Difficult to control film thickness: It can be difficult to achieve a uniform film thickness.

Roll Coating Method

-

Advantages

- High efficiency: Continuous process, suitable for mass production.

- Thickness uniformity: High film thickness uniformity.

-

Important points to note

- High cost: Equipment is expensive and initial investment is large.

- Material limitations: May not be suitable for certain materials.

The dip coating method is used in many industrial and research fields.

The advantages of the dip coating method are its simplicity, cost-effectiveness and versatility.

While other coating methods each have excellent characteristics for specific applications and conditions, the dip coating method:

- 1. Low capital investment

- 2. Wide range of applications

- 3. Less material waste

For these reasons, the dip coating method has been adopted in many industries and research fields.

It is especially valued for its versatility and cost-effectiveness.

Japanease

Japanease English

English